Increase in human population and rapid

industrialization has increased the burden on already limited natural resources

of energy production like fossil fuel. Industrial process wastes a lot of

energy which can be extracted and used to meet human need. Organic Rankine Cycle ORC is one of the

processes which can be operated even on low waste energy. Organic Rankine Cycle ORC are also being

installed in vehicles to extract waste heat from radiator and on diesel engine

exhaust. Fluids for Organic Rankine Cycle ORC either refrigerant or any organic fluid which is

selected on basic of ISO 817:2014/AMD

1:2017, ISO 17584:2005 and ISO 11650:1999 standards.

Introduction

Today’s world has a never ending demand of energy due to continuous increase in the world population, rapid industrialization and highly dependence of humans of electrical and thermal devices to meet day to day needs. This never ending demand of the energy has forced the maximum utilization of the limited natural resource for the energy production purpose. The quantity of the fossil fuel is limited but the conventional energy generating systems are not effectively converting and utilizing the energy produce by burning the fossil fuel due to design and process limitation. According to the world energy consumption report about the use of energy by the geographical regions and the use of natural resources to meet the need of energy, the requirement of energy will only increase in future but the availability of the natural resources will decrease. So there is a need of setup which can extract the maximum energy from the existing energy generation or processing systems to meet the world energy need.

Figure 1 global energy consumption [(energy matter, 2017).

Figure 2 energy consumption by resources (energy.gov, 2017).

One of the methods to extract the maximum energy out of the system is to utilize the energy being wasted into the environment. The wasted energy can be utilized to do useful work which either part of the same process like ventilation cooling system that utilize the low temperature air to cool down the fresh air or the completely separate system like waste energy recovery organic Rankine cycle power plant that utilize the waste heat rejected by a system to heat an organic fluid which then is used to power turbine for energy production.

Organic Rankine Cycle for Waste Energy Recovery

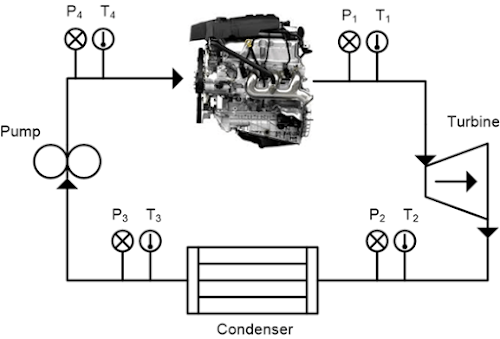

Organic Rankine cycle power plant are just like a standard Rankine cycle power plant with the only difference is that an organic fluid is used as a working fluid instead of water. Benefit of utilizing the organic fluid instead of water is that organic fluid require very less heat to get vaporize as compared to water which enable this power plant to operate at the low waste heat of different process for energy recovery process. Recently a lot of work is being done to develop small scale organic Rankine cycle power plant which can extract waste energy from low heat waste process. Yinji (2018) worked on the development of the organic Rankine cycle power plant which can run of the waste heat of the vehicle exhaust and engine waste heat of radiator. According to work 30% of the heat developed inside engine is wasted by the radiator which can be utilized by the specially designed organic Rankine cycle to produce and store electrical energy. The electrical energy produce can be utilized to power the vehicle after engine is turn off.

Figure 3 ORC integrated in Honda vehicle

Other than the vehicle the internal combustion engine which use diesel as a fuel are used for the electricity production purpose in many industries. These engines waste about one third of the heat produce in engine cylinder through the exhaust gases. Cipollone (2015) worked to develop an organic Rankine cycle power plant which can operate on the exhaust gases of the internal combustion engine to produce electricity using its own turbine and generator system. Regular work conditions (regular load) and off work conditions (maximum load) were tested in this setup and result show the overall efficiency of 4% which includes 4.8% for the regular working conditions and 4.4 percent for off work conditions. As organic Rankine cycle combines two different engineering fields which include refrigerants and power plant setup so two different ISO standards are used to develop, evaluate and improve these power plants. A special purpose turbine will be used for ORC so ISO 10437:2003 revised in 2017 will be used for development, evaluation and improvement of ORC along with the ISO 10494:2018 for noise pollution. As per energy related product directive (ERP) of European commission the minimum efficiency of the machined used for energy recovery system should 75 % by the year 2015 and should reach 80 to 85 % by the year 2017.

Organic Fluids of ORC

Organic fluid used in organic Rankine cycle is one of the most important factors in defining the efficiency of the plant. Kamyar (2015) worked on nine different fluids of organic Rankine cycle which includes refrigerants (R 134a, R123, R227ea, R245fa, R600) and organic fluid (Iso butane, Iso pentane, n pentane and toluene) in order to find the best working fluid. Result show that for the given condition refrigerant R134a and organic fluid n-butane provide best result in terms of overall efficiency of 21.3 % and 21.9 % respectively. Working fluids for organic Rankine cycle are selected based on criteria which includes requirements like environment sustainability, ozone depletion potential, global warming potential, safety (non-toxic, non-corrosive and non-flammable) and properties like critical vapor pressure, critical temperature and thermal stability (Kamyar, 2015). Hung (2019) worked on the development of a small scale organic Rankine cycle for waste heat recovery and investigated the effect of pure refrigerant and mixture of refrigerant on the performance of the organic Rankine cycle power plant. Two pure liquids R 245 fa and R 123 and two mixture 67 % R 245 fa with 33 % R 123 and 33% R 245 fa with 67 % R 123 were test and result show that the performance of pure fluid or mixture depends on the working parameters of the organic Rankine cycle. Working parameters includes working pressure, temperature, pressure ratio and the mass flow rate of the fluid. For refrigerants ISO 817:2014/AMD 1:2017 designate and classify the safety of refrigerant, ISO 17584:2005 defines the properties and ISO 11650:1999 define the refrigerants recycling and recovery. All these refrigerants are used to select the proper refrigerant for ORC. Other than this general ISO rules which includes, ISO 9001:2015 for standard quality, ISO 14001:2015 for environmental protection and ISO 45001:2018 for safety and health standard are used for the advancement and future development of energy recovery organic Rankine cycle.

No comments:

Post a Comment