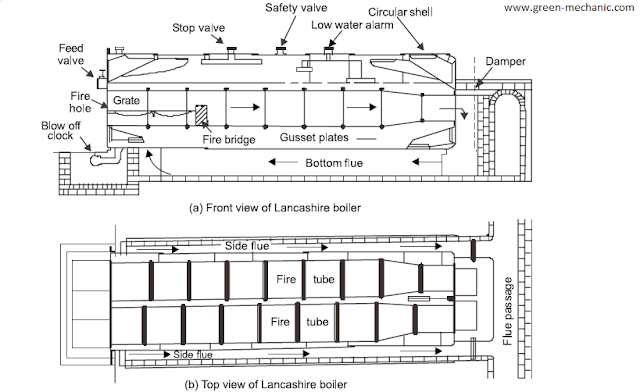

LANCASHIRE BOILER is a simple horizontal boiler and belong from the shell and tube types of boilers.

It has a circular shell connected to end plates supported by gusset plates. It has a circular shell connected to end plates supported by gusset plates.

Lancashire boiler have two fire tubes whose length is equal to length of the boiler and diameter of the fire tube is less than half of the diameter of the shell.

You can read our other article to know all about Locomotive boiler Parts, Working and Applications and Cornish Boiler: Parts, Working, Advantages, & Disadvantages

Parts of LANCASHIRE BOILER

Grate

Feed valve

Fire hole

Safety valve

Bottom flue

Side flue

Low water alarm

Dampers

Blow-off clock

Fusible plug

Working of LANCASHIRE BOILER

In Lancashire boiler fuel is added into the grate of the boiler and burning of this make gases hot. These hot gases start their motion from grate section and enter the fire tube of the boiler.

Hot gases enter at the front section of the boiler and leave the boiler from the back and enter the bottom fuel and start moving toward the front section of the boiler.

At front section hot gases leave the bottom flue and enter in side flue and move again toward the back of the boiler and enter the main outlet there.

There is 85% heat transfer when hot gases are in fire tube and 15% when they are in bottom and side flue. Pressure range of the boiler is about 0.7 MPa to 2 MPa and efficiency is 65 to 70%.

Dimension of the boiler depends on the dimension of the shell which is 2 to 3 m is diameter and 6 to 10 m in length.

Lancashire Boilers are used to drive

- Steam turbines

- Marines

- Locomotives

Lancashire Boilers are used in industries as processing agent

- textile industry

- paper industry

- sugar industry

- tire industry

- chemical industry

- breweries industry

Advantages of Lancashire Boiler

- Lancashire Boiler is an Economical boiler

- It can be easily operated

- Compactness

- Portability

- Simple design

- Easy construction

- Have low maintenance cost

- High overall efficiency (80% to 85%)

- Steam produce have excellent quality

- Due to the large quantity of water available, it can easily overcome the load fluctuation

Disadvantages Lancashire Boiler

- Corrosion in water legs

- It is difficult to clean inside

- Low steam production rate (9000kg/hr)

- Horizontal structure cover more ground space

- Maintenance of brick work is tedious.

- Have limited grate area because the fire tubes have small diameter.

- It’s a low pressure Boiler maximum limit is only 20 bars

Thank you very informative topic

ReplyDeletemy email is : qusay.steamboiler@yahoo.com

You are most welcome Quay Abdulelah

Delete