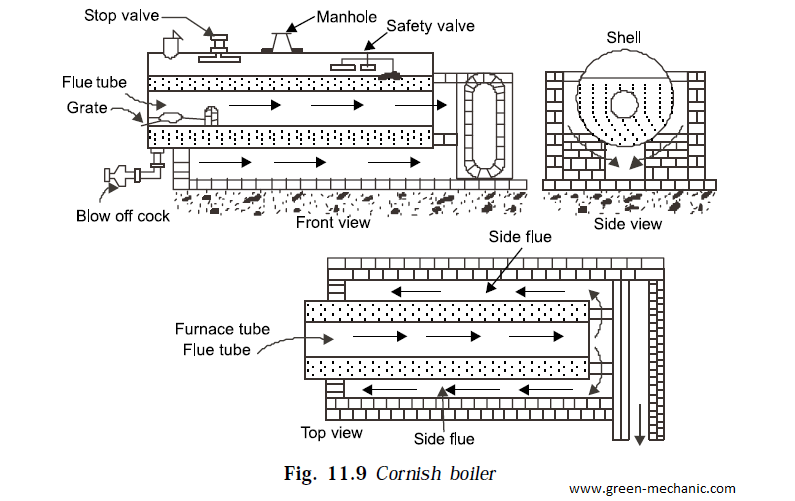

Cornish boiler is a simple horizontal boiler which belong to the shell and tube class of boilers. Cornish boiler is much like the Lancashire boiler.

Cornish boiler has the ability to produce steam at the rate of 1350 kg/hr and can take the maximum pressure of about 12 bar.

Dimensions of the Cornish boiler shell is 4 m to 7 m in length and 1.2 m to 1.8 m in diameter. Cornish boiler is a fire tube type of boiler that is hot gases flow in tubes and water surround these tubes in shell.

Parts of Cornish boiler

Working of the Cornish boiler

Fuel is added in the grate area where it burn to produce hot gases. There hot gases move into the fire tube which take it inside the shell where it exchange its heat with surrounding water. Water take heat and after some time it start boiling to produce steam.

Hot gases upon reaching at the end of the fire tube, divided into two section and each move into the one of two side flue which take them once again at the front section of the boiler where they are move into the bottom flue and bottom flue take them toward the chimney. Chimney throw these gases out of the boiler into the atmosphere.

In this process hot gases travels complete length of boiler thrice that is once in fire tube then in side flue and at last bottom flue. Maximum heat transfer is taken place at fire tube and shell section then taken place at side flue and at last at bottom flue.

Application of Cornish boiler

- Cornish boiler are used in many industries like textile, sugar, paper, tyre, chemical etc

- They are also used to produce steam to run steam turbine

- They are also used in many marines

Advantages of Cornish boiler

- Cornish boiler have simple design and easy construction

- One of its main advantages is its Compactness and Portability

- Low construction and maintenance cost

- It has ability to overcome load fluctuation

Disadvantages of Cornish boiler

- Low steam production rate = 1350 kg/hr

- Low maximum steam pressure range 12 bar

- Need more ground because of horizontal structure

you should mention its characteristics such such as single tube boiler, low pressure horizontal etc. this would really help understand better

ReplyDeleteThank's for recommendation. We will work o this and update the article the soon.

DeleteREALLY FANTASTIC...HELPED ALOT

ReplyDelete