Shell molding is the expandable mold metal casting process in which mold is a thin shell of sand held together by the binder usually a thermosetting resin. It was invented by the German in about 1940s. Thickness of the shell mold is about 9 mm

Steps involves in Shell molding

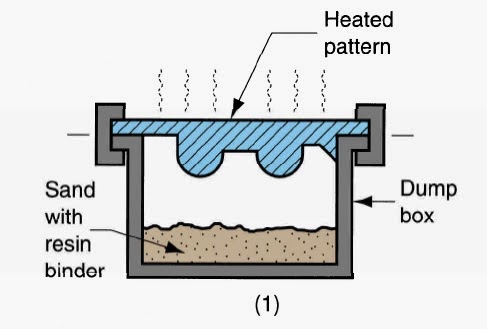

Step 1

A metal plate is used to make the pattern. Shape of the patter is like the shape of shell mold you need. Metal plate is heated and they fixed on a container containing the sand and the thermosetting resign.

Step 2

Container is inverted so that the sand and thermosetting resign may came into contact with each other. Heated plate melts the resign and makes a shell of sand around the pattern.

Step 3

In order to remove the extra sand and uncured resign container is reposition again and plate is detached from it

Step 4

Shell made is not properly cured yet so it is heated in a heater for proper curing.

Step 5

After proper curing shell mold is removed from the patter.

Step 6

Same process is preformed to make the other half of the mold and then both halves are attached in a box and supported by the sand. Molten metal is poured.

Step 7

Finish metal product is removed from the shell mold

Advantages of shell molding

- Smother surface of the mold,

- Ease for the molten metal to flow.

- Good dimensional accuracy.

- Machining is not required.

- Usually no cracks in casting.

- Mechanizing for mass production gives good results

Disadvantages of Shell Molding

- Most expansive metal pattern.

- Takes more time.

- Not suitable for small production

No comments:

Post a Comment