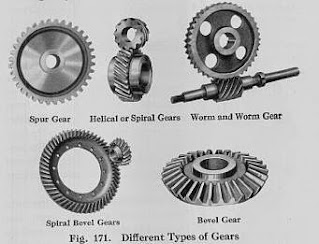

There are five types of gears namely: spur gear, helical gear, bevel gear, worm gear (worm and worm wheel), and rake and pinion gear.

Based on advantages and disadvantages of different types of gears, each type of gear is used for a different purpose and these gear types manly differentiate based on how they transfer power.

|

| Different Types of Gears |

Spur gear

Spur Gear is one which has teeth profile cut parallel to the axis of the gear as shown above. It is used for transfer of power in parallel shafts.Advantages and Disadvantages of Spur Gear

Advantages of spur gear

- They offer constant velocity ratio

- Spur gears are highly reliable

- Spur gears are simplest, hence easiest to design and manufacture

- A spur gear is more efficient if you compare it with helical gear of same size

- Spur gear teeth are parallel to its axis. Hence, spur gear train does not produce axial thrust. So the gear shafts can be mounted easily using ball bearings.

- They can be used to transmit large amount of power (of the order of 50,000 kW)

Disadvantages of spur gear

- Spur gear are slow-speed gears

- Gear teeth experience a large amount of stress

- They cannot transfer power between non-parallel shafts

- They cannot be used for long distance power transmission.

- Spur gears produce a lot of noise when operating at high speeds.

- when compared with other types of gears, they are not as strong as them

Helical Gear

Helical Gear is one which has teeth profile cut at an angle with respect to the axis of rotation of the gear as shown above. It is used for the smooth transfer of power in parallel shafts with very low noise.Advantages and Disadvantages of Helical Gear

Advantages of helical gear

- The angled teeth engage more gradually than do spur gear teeth causing them to run more smoothly and quietly

- Helical gears are highly durable and are ideal for high load applications.

- At any given time their load is distributed over several teeth, resulting in less wear

- Can transmit motion and power between either parallel or right angle shafts

Disadvantages of helical gear

- An obvious disadvantage of the helical gears is a resultant thrust along the axis of the gear, which needs to be accommodated by appropriate thrust bearings, and a greater degree of sliding friction between the meshing teeth, often addressed with additives in the lubricant.

- Thus we can say that helical gears cause losses due to the unique geometry along the axis of the helical gear’s shaft.

- Efficiency of helical gear is less because helical gear trains have sliding contacts between the teeth which in turns produce axial thrust of gear shafts and generate more heat. So, more power loss and less efficiency

Bevel Gear

Bevel Gear is one which has teeth profile cut on a conical surface which is parallel to the axis of the gear as shown above. It is used for transfer of power in perpendicular shafts (shafts that meet at an angle of 90 degree).Advantages and Disadvantages of Bevel Gear

Advantages of Bevel Gear

- This gear makes it possible to change the operating angle.

- Differing of the number of teeth (effectively diameter) on each wheel allows mechanical advantage to be changed.

- By increasing or decreasing the ratio of teeth between the drive and driven wheels one may change the ratio of rotations between the two.

- Meaning that the rotational drive and torque of the second wheel can be changed in relation to the first, with speed increasing and torque decreasing, or speed decreasing and torque increasing.

Disadvantages of Bevel Gear

- One wheel of such gear is designed to work with its complementary wheel and no other.

- Must be precisely mounted

- The shafts' bearings must be capable of supporting significant forces.

Worm gear (worm and worm wheel)

Worn Gear (Worm and Worm Wheel) is one which has single teeth profile cut in a manner it look more like a screw, as shown above.

It is used for transfer of power in perpendicular shafts (shafts that meet at an angle of 90 degree). Wheel gear is a simple spur gear.

Advantages and Disadvantages of Worm gear (worm and worm wheel)

Advantages of worm gear

- Worm gear drives operate silently and smoothly.

- They are self-locking.

- They occupy less space.

- They have good meshing effectiveness.

- They can be used for reducing speed and increasing torque.

- High velocity ratio of the order of 100 can be obtained in a single step

Disadvantages of worm gear

- Worm gear materials are expensive.

- Worm drives have high power losses

- A disadvantage is the potential for considerable sliding action, leading to low efficiency

- They produce a lot of heat.

Pinion Gear

Advantages and Disadvantages of Rack and Pinion

Advantages of Rack and Pinion

- Cheap

- Compact

- Robust

- Easiest way to convert rotation motion into linear motion

- Rack and pinion gives easier and more compact control over the vehicle

Disadvantages of Rack and Pinion

- Since being the most ancient, the wheel is also the most convenient and somewhat more extensive in terms of energy too.

- Due to the apparent friction, you would already have guessed just how much of the power being input gives in terms of output.

- A lot of the force applied to the mechanism is burned up in overcoming friction, to be more precise somewhat around 80% of the overall force is burned to overcome one.

- The rack and pinion can only work with certain levels of friction.

- Too high a friction and the mechanism will be subject to wear more than usual and will require more force to operate.

- The most adverse disadvantage of rack and pinion would also be due to the inherent friction, the same force that actually makes things work in the mechanism.

- Due to the friction, it is under a constant wear, possibly needing replacement after a certain time

Advantages and disadvantages of different types of gears are shown above and base on that one can decide which types of gears you need to work with.

tx brother.

ReplyDeleteMy pleasure :-)

DeleteSir please tell me the answer

DeleteWorm and wheel is a self locking machine ?what are the reason

due to the design worm and worm wheel, power can only transfer from worm to the wheel. No power transfer from wheel to worm make it self locking machine

Deletethanks a lot

ReplyDeleteYou're Welcome

DeleteA gear without bearings is not play its operation and also the gear work is based on the bearings work.

ReplyDeleteHi NISSI HRB,

DeleteYou probably want to say that each gear is mounted on a shaft that needs a bearing support on both of its ends.

what is double helical gear and what are its advantages

ReplyDeleteDouble helical gears offered by us are also known by the name of Herringbone gears. These gears have two sets of teeth which are set in V shape and functions as two mirrored helical gears joined together. The mirrored arrangement cancels out net axial thrust as each half of gear thrusts in opposite direction.

DeleteWhat are advantage & disadvantage of various tooth profile used in speed reduction ??

ReplyDeleteHi Ganesh Hogale, sorry for late reply we were little busy in a project. We have noted down your request and will send you a response within one week.

DeleteRegards,

Thanks :)

ReplyDeleteMost welcome

DeleteGood Effort.....

ReplyDeleteThanks :-)

DeleteI am working on a project that involves a set of gear combinations mounted on different shafts that transmit torque to the cam shaft. This is a low torque/low speed application. I would like to get some help with design guidelines for the drive shaft, bearings and gear arrangements.

ReplyDeleteI found it most reliable of all such sites.. Great job

ReplyDeleteI am working on a project in which I want a minimal amount of noise during operation using two gears mounted in a parallel configuration. I picked out a helical bevel gear but they are not meshing properly. Above you mention that the helical gears can be mounted in a parallel configuration.

ReplyDeletecheck there module. both gear should have same module for proper meshing

Deletemajorly for all helical gears--the pressure angle also matters

ReplyDeleteGenerally,it is less than 20 degrees as per my knowledge.

few supplier also supply pressure angle of 25 degrees.

basically,the tangential force or stress per area will be the actual torque shared by any of the two teeths..so pressure angle also important.

what is the merit/demerit of increasing the worm gear teethes?

ReplyDeleteWhat are the advantages of hypoid gears in final dive ?

ReplyDeleteI AM STUDENT IN MECHANICS ENGINEERING, I WANT TO BEST ENGINEER

ReplyDeleteRead books

Deleteadvantage and distadvantage of hypoid gear and also application of hypoid gear

ReplyDeleteDescribe the various VVT technologies used in modern automobiles?

ReplyDeleteThanks

ReplyDeleteAnd must welcome

been very helpful, thank you.

ReplyDeleteWhat effects can one have on the gear box after engaging neutral gear while the car is in motion? Is it safe to do so?

ReplyDeletedoes using a herringbone gear on a rack and pinion increases its efficiency and reduces friction? thank you

ReplyDeleteIt will provide smooth power transfer but efficiency and friction have nothing to do with this.

DeleteNice efforts , thanks a lot :-)

ReplyDeleteBest & Precise answer. Thanks a lot ;)

ReplyDelete