Permanent Mold Casting Processes are one in which there is a one mold made of metal which could be used again and again many times. Mold material is usually cast iron or steel. Mold is usually consist of two parts, which are attached to each other and metal is poured and when metal cools, mold is opened and part is removed

Basic Permanent Mold Casting Processes

- Die casting

- Hot chamber die casting

- Cold chamber die casting

- Centrifugal casting

- True centrifugal casting

- Semi centrifugal casting

- Pressure casting

- Vacuum molding casting

- Slush casting

- Ingot manufacturing

Steps involves in Permanent Mold Casting Processes

Step 1

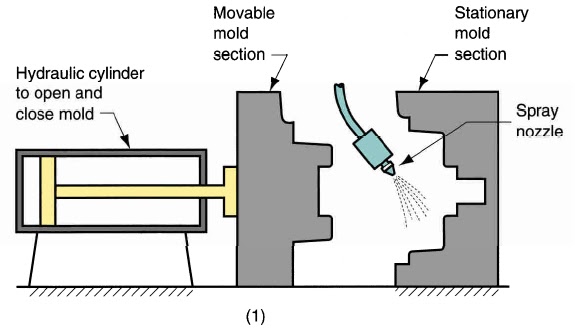

Two parts of the mold are heated and are spared with some material which prevent the molting material from sticking with mold walls.

Step 3

After the mold is closed molten metal is poured into the mold.

When the molten material is cool then then mold is open and part is removed

Applications Permanent Mold Casting Processes

- Because of the high initial cost of the mold. These types of process are suitable for the mass production

- Parts casted are piston, pump bodies, car engine parts, air craft parts etc

- Metals cast: aluminum, magnesium, copper-base alloys, and cast iron

Advantages Permanent Mold Casting Processes

- High dimensional accuracy

- Good surface finish

- High production rate

- Low cast of product

Disadvantages Permanent Mold Casting Processes

- High initial cost

- Limitation of material (low melting metals only)

- Only simple geometry

No comments:

Post a Comment